Quality Management System

Engineering & Construction Quality Management

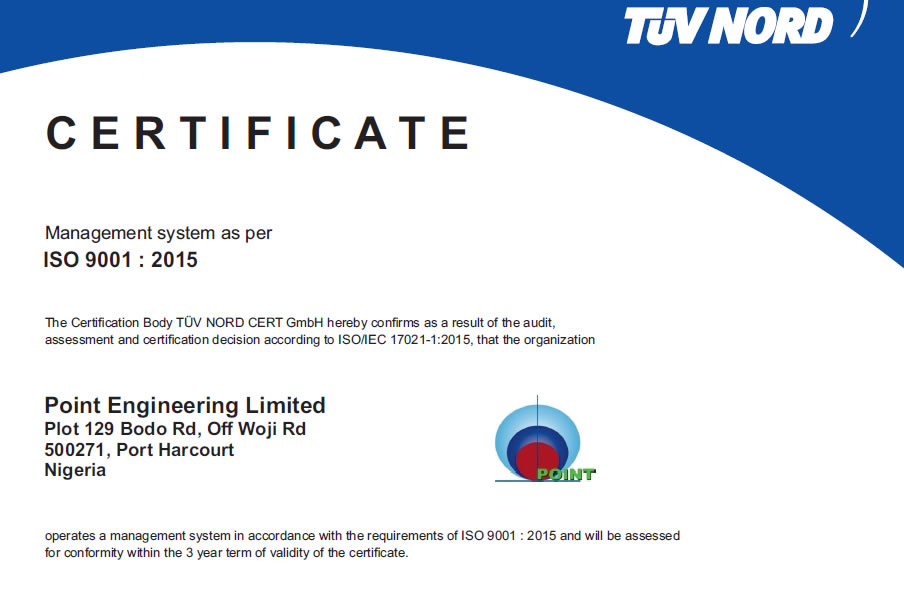

At POINT Engineering, one of the ways we keep up our commitment is to ensure we comply with best management practices.

Our Quality Management System for Engineering:

The Engineering phase is a very crucial stage for all our EPCI (Engineering, Procurement, Construction and Installation) and hence critical to the success of our projects.

Our QMS for Engineering involves planning, analyzing and executing sound technical checks of all our project interdiscipline deliverables. A lot goes into our Engineering planning and execution activities.

The diligent efforts of our qualified engineering resources, our well documented processes, plans and compliance with QMS has always increased our success rate of executing our engineering operations.

Our Quality Management System for Procurement:

Our QMS for procurement is robust and well developed such that there's a minimal procurement planning and execution risks.

Some of our QMS procurement planning and execution activities include but not limited to;

- Manpower planning

- Clear defined roles

- Bid invitation and evaluation process

- Purchase Order (PO) - involving negotiation, award, administration and close-out process

- Review and approval process

- Risk identification and mitigation plans for procurement risks.

- Change order process related to procurement activities

Our Quality Management System for Construction:

From experience, we've learnt to maximize the effectiveness of our construction management via well planned and managed construction activities. Our QMS is integrated with constructability principles. Some of our QMS construction planning and execution activities include but not limited to;

- Interface management with engineering, procurement and other functions

- Construction hazard identification review plan

- Manpower planning

- Preservation and maintenance requirements, process and monitoring mechanism

- Schedule for constructability reviews

- Non-management process for construction activities

Our Quality Management System for Installation:

Our wealth of experience in onshore/offshore installation operations have shown to consist of complex web of activities from mobilization to demobilization. We have a documented system in our QMS for Installation that helps minimize rework and greatly improve the quality of work we do.

Our QMS Installation planning and execution activities include but not limited;

- SIMOPS (Simultaneous Operations) identification and plan

- Vessel assurance program

- Non-conformance management process for onshore/offshore installation activities

- Schedule for readiness reviews and hazard identification and plan

- Training plan for onshore/offshore resources

- Review and approval process for offshore installation deliverables along with identification of qualified reviewers and approvers

- Installation analysis by scope